PCB Assembly Service Evaluation: Part 1 (Introduction)

What are you even talking about?

I think we've become accustomed to inexpensive PCB manufacturing services by now, and it has really been a boon to the DIY electronics community. Much more convenient than etching circuit boards yourself, although I have some fond memories of that... Component assembly on the other hand is still something that most hobbyists do by hand, as far as I know. It's usually not a big deal for smaller one-off projects and you don't need specialized tools or nasty chemicals like for etching PCBs. Also, it used to be pretty expensive to order assembly from the PCB manufacturer as well.

So why don't we keep doing the assembly ourselves?

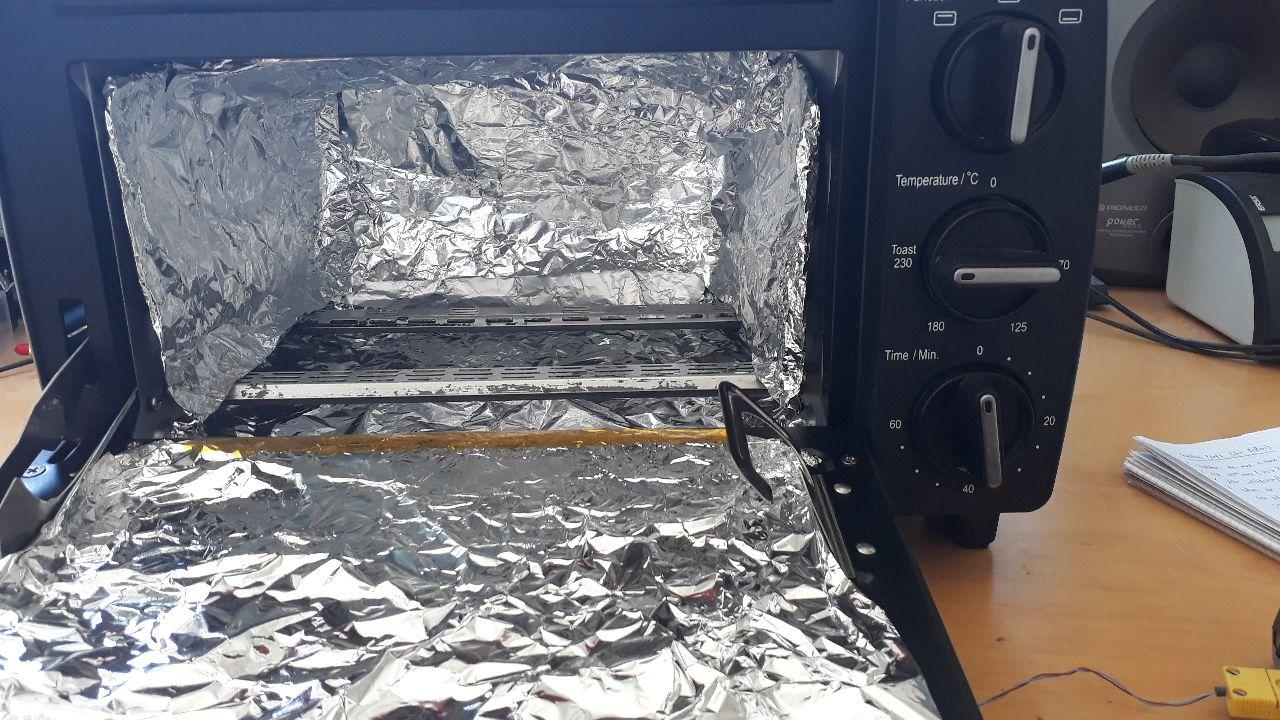

For many projects it doesn't make much sense to order assembly. One or two PCBs with some SOIC chips and 0805 passives? Just use the soldering iron. A PCB with QFN or even BGA chips and smaller passives? Reflow it in the toaster oven, works great! But even if you use a reflow process, you still need to place the

parts on the PCB. If you either need more than a few boards or if your design uses a huge amount of parts, placing them by hand can get very tedious. That might be the right time to think about ordering assembly with your board.

Modified toaster oven for reflow soldering

Modified toaster oven for reflow soldering

Okay Mr. Smarty-Pants, what do you know about that?

Not much really. I've only done it maybe once or twice, years ago when I was briefly working as a PCB designer before my studies. I wanted to use an assembly service for the FPGA board I designed as part of my bachelor thesis last year, but the situation was very uncertain because of the ongoing pandemic. Faced with the decision to either have the board assembled and potentially suffer catastrophic delays, or trying to assemble and reflow it (including the BGA FPGA chip) myself in a toaster oven, I chose the latter option. Luckily, it turned out great. But still, I would like to try and get one of my own projects assembled just to see how it turns out and what it actually costs. Gain some experience on the current state of hobbyist PCB assembly services, so to say.

Get to the point already! Which project?

Well, currently I don't have an ongoing project which would particularly benefit from using an assembly service. But maybe we can do a little test project, just for this evaluation? Something that uses a huge amount of the same SMD parts... Of course, an LED matrix! But let's keep it simple, no programming or complex or expensive chips, only parts that the assembly service provider already has in storage. I think just a random blinky LED matrix powered by a linear-feedback shift register (LFSR) would be great. Not very useful, but simple and pretty to look at. I've done something similar in the past, for a 1024-LED matrix, with a multiplexing driver chip capable of dimming with PWM. The result was mesmerizing! You can see the hardware in action in the video below. But this time, we'll keep it simple; only 64 LEDs and no dimming. That should be enough for an assembly test run.

Demonstration of the "OutOfSync" 1024-LED matrix hardware built some time ago

Great, which assembly service will have the honor to produce this useless piece of "art"?

At this point I obviously can't and won't recommend any of them. But I've decided to try the JLCPCB PCB manufacturing and SMD assembly service. It seems really inexpensive and I've recently read something about free assembly, so I'll check that out. That's obviously not a proper evaluation of the available options, but it's just a test run and surely I'll be fine. So for the next part of this mini-series I'll be back with a design draft and selected parts from the JLCPCB stock. See you back, hopefully!